Key equipment in the country's petrochemical, thermal power, nuclear power and other energy fields began to be put into mass production in the 1980s and 1990s. Up to now, it has approached or even exceeded its initial design life (already in extended service). Since most of them work in harsh conditions, such as high temperature, high pressure and strong corrosive environment, their mechanical performance will undergo significant aging with the increase of service time, leading to a decrease in load-bearing capacity and an increase in the risk of failure. As of the end of 2020, there are 4,396,300 units of pressure vessels in China, in addition to 355,900 boilers, 179,000,000 gas cylinders, and 1,012,600 kilometers of pressure pipelines. According to statistical estimates from the Ministry of Emergency Management, approximately 60 major safety accidents in the petrochemical industry occur in the country every year, of which nearly 30% are related to equipment aging. For example, in 2015, the main steam pipe of a 125MW unit of a thermal power plant burst after a cumulative operation of 158,400 hours, and it is believed that extended service is the main cause of the accident after analysis. Therefore, energy equipment in extended service has always been the focus of safety supervision of the company. Many documents issued by the government have put forward higher requirements for the safety of energy equipment, especially special equipment. “The Thirteenth Five-Year Plan for the Development of Safety Production Standards” points out that prevention should be given priority and Chinese safety production technology level should be improved.

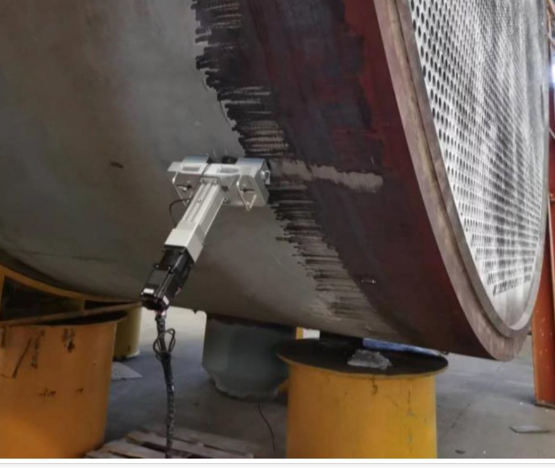

At present, the aging and life extension assessment of large energy equipment, such as pressure vessels, requires the mechanical performance data of materials after service. The traditional detection method is destructive and requires cutting and sampling at key parts of the pressure vessel (welding seams, stress concentration areas), and then conducting experimental tests. Such damage results in shutdown of equipment and pipelines, as well as serious economic and social losses.

Therefore, there is an urgent need for the equipment that can non-destructively test the mechanical performance of in-service equipment to help companies make scientific life extension and replacement decisions, avoid pollution and waste caused by unnecessary replacement of equipment that still can be used and greater environmental pollution and safety risks caused by the use of over-aging equipment.

Hot line:

139-6180-2200 /

135-1164-0818

Hot line:

139-6180-2200 /

135-1164-0818